Cnc Programming Basics

- 1. CNC Programming Basics Program structure Every program consists of: Program Start The program start is the program number. The program number begins with character/letter O . Program Contents NC blocks Program End M30 for a main program M17 for a sub-program

- 2. CNC Program Numbers Program Numbers O 6999 . . . O 0256 O 0255 . . . O 0000

- 3. CNC Program Blocks (1) N is the address Block numbers from N0000 to N9999 A block consists of number and words Words are contents of a block Block numbers are selected in the jumps of ten for the purpose of insertion

- 4. CNC Program Blocks (2) A block consists of one or more blocks A Word consists of a character (address) and a number. Every address has a certain meaning, on which the corresponding number depends

- 5. CNC Prg. Syntax Regulations The maximum block length must not exceeded four lines. If max. length exceeded alarm 650 occurs. Every block starts with a block number. After the block numbers follows the G command. Words consists of coordinates X(U) , Z(W) . For G02 , G03 program interpolation parameter I and K are placed after X(U), Z(W). The F word (feed, thread pitch). The S word (cutting speed). The T word (tool address). The M word (additional functions).

- 6. Absolute Value Programming P0 N… … P0 P1 N… G01 X40. Z25. F… P1 P2 N… G01 X60. Z-40. F… P2 N… … Absolute coordinate system Example:

- 7. Incremental Value Programming Incremental coordinate system Example: P0 N… … P0 P1 N… G01 U5. W-25. F… P1 P2 N… G01 X10. Z-15. F… P2 N… …

- 8. Mixed Programming Mixed coordinate system Example: P0 N… … P0 P1 N… G01 U5. W-25. F… P1 P2 N… G01 X60. Z-15. F… P2 N… …

- 9. Self-holding Functions (1) The majority of G and M commands and other words are self-holding, remain active until overwritten or deactivated/deselected. Aimed to simplify and to reduce programming tasks. Example: G41 can be deactivated by issuing G40 command .

- 10. Self-holding Functions (2) Take-over of G00 commands in block N0110 In block N0120 G00 is deactivated by G01. G01 is active. N0050 M03 N0060 … … N0120 M04 Example 1: Example 2: M03 activated at N0050 and effective from N0050 through N120. M03 deactivated at N0120 by M04 command N0100 G00 X50. Z+10. N0110 X36. Z+2. N0120 G01 X40. Z-10. F…

- 11. Reference Points M = Machine zero point. (unchangeable ref. Point determined by machine manufacturer) N = Tool mounting reference point W = Work piece zero point. (can be freely determined by the programmer and can be moved within program

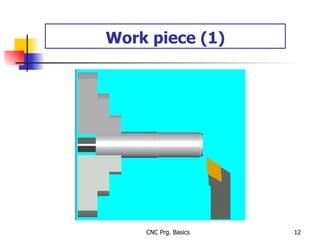

- 12. Work piece (1)

- 13. Work piece (2)

- 14. G & M Commands G00: Rapid traverse G01: Linear interpolation G02: Circular interpolation clockwise G03: Circular interpolation counter clockwise G70: Measuring in Inch (USA) G71: Measuring in mm (Other countries) M03: Spindle ON clockwise M04: Spindle ON counter clockwise M20: Tailstock back M21: Tailstock forward

- 15. G 00, Rapid Traverse Absolute dimensions of the target point coordinates: N030 G90 N040 G00 X48 Z-26 An absolute X coordinate related to the diameter. Incremental dimensions of the target point coordinates: N030 G91 N040 G00 X-10,5 Z-31 Tool position X69 Z5

- 16. G 01, Linear Interpolation P0: tool position G90: N030 G00 X39 Z2 N040 G01 X39 Z0 N050 G90 N060 G01 X48 Z-37 G91: N030 G00 X39 Z2 N040 G01 X39 Z0 N050 G91 N060 G01 X4.5 Z-37 G01 X… Z…

- 17. G 90 & G91 Commands G90 G01 X+140 Z-90 Target point abs. G91 G01 X+40 Z-60 Target point incr. PO: Start Point P1: Target Point

Editor's Notes

- #2: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #3: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #4: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #5: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #6: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #7: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #8: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #9: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #10: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #11: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #12: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #13: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #14: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #15: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #16: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #17: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002

- #18: Computer Numeric Control @ UPH By Jonny Latuny, M.Eng © August 2002